Cellulose Nano Fiber (CNF) AronFibro Rubber Masterbatch

AronFibro MB is a rubber masterbatch which capitalizes on the easy dispersiveness of our CNF. It is possible to achieve both elasticity and breaking strength while maintaining rubber-like properties. It contains 20 phr of CNF. It is also characterized as being easy to handle because it maintains good CNF dispersiveness even with rubber dilution.

Usage

- Environment and energy

- Reduce environmental impact

- Basic materials

- Resin and rubber additives Paint, ink, coatings and adhesives

- Lifestyle

- Apparel and textiles Packaging materials

Function

Barrier and protection

High strength

Abrasion resistance

Features

- This is a masterbatch of CNF obtained with our unique manufacturing method combined with rubber in a high concentration.

- We make it by mixing and drying the CNF aqueous dispersion and rubber latex (Fig. 1).

- The carboxy group in CNF is the sodium salt form (-COONa).

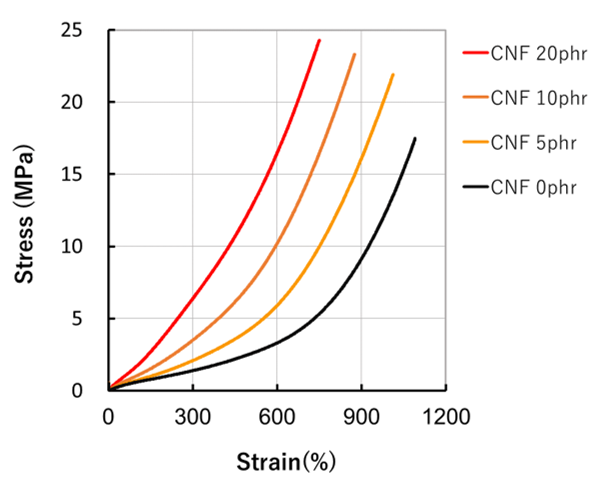

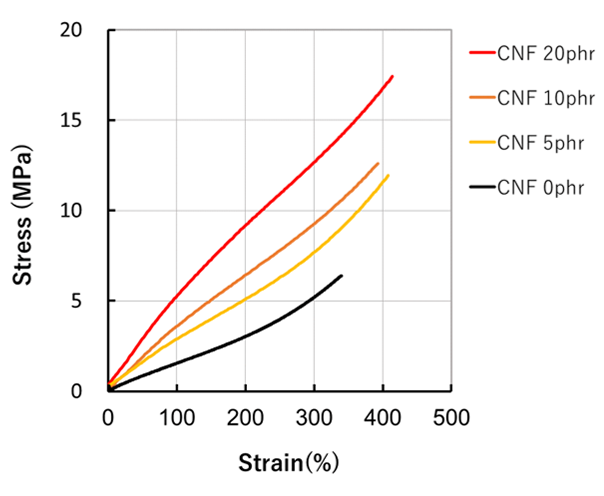

- It disperses well in rubber. Therefore, it is possible to increase the Young’s modulus while maintaining the inverted-S-shaped stress—strain curve unique to rubber (Fig. 2-1 and 2-2).

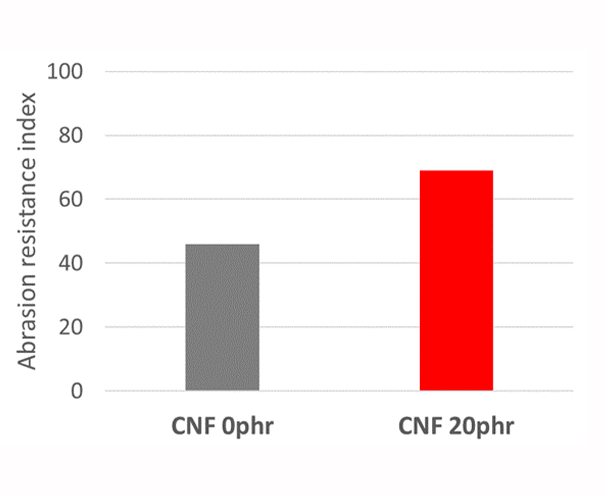

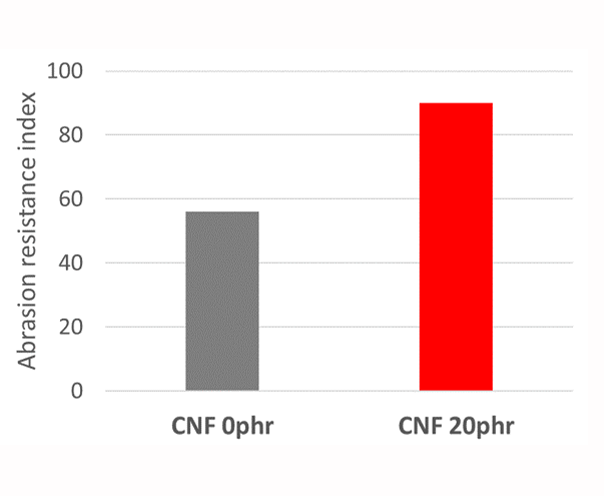

- It is possible to raise the abrasion resistance by adding it to rubber (Fig. 3-1 and 3-2).

Usage and Specification

- We provide a product containing 20 phr of CNF addition with natural rubber and NBR serving as the matrix.

General characteristics

Leaflet: AronFibro T-OP100 Chemical Characteristics[PDF:848KB]

Inquiries

New Products Development Division

Cellulose Nano Fiber Section

Cellulose Nano Fiber Section

*9:00 am - 5:00pm (except weekends and holidays)

Search products by key word