ARONBULLCOAT

For repair work on civil engineering structures, such as bridges (superstructure, substructure, footing, etc.), caissons and piers

ARONBULLCOAT is an acrylic rubber surface coating that extends the lifespan of civil engineering structures by protecting against salt damage, alkali-aggregate reactions, neutralization and freeze damage, which cause early degradation of concrete civil engineering structures.

- Product Name

-

ARONBULLCOAT

Features

The unique properties of acrylic rubber extend the lifespan and prevent early degradation of civil engineering structures

Civil engineering structures that support our life today represent important social capital that must be passed down to future generations.

With momentum growing in recent years to better maintain this social capital, the early degradation of civil engineering structures through salt damage to concrete, alkali-aggregate reactions and neutralization has become a serious and urgent problem to address, including establishing preventive technologies.

ARONBULLCOAT developed by Toagosei is a super-flexible thick membrane type acrylic rubber surface coating that offers various unique properties for preventing the early degradation of civil engineering structures.

Features of ARONBULLCOAT

Delivers excellent coverage of cracks

Acrylic rubber is the most flexible and durable of any rubber-type polymer material. ARONBULLCOAT leverages these characteristics to deliver superior, sustained, and long-term coating coverage of cracks that occur in concrete base material.

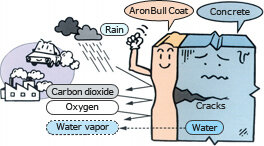

Prevents causes of structure degradation

Acrylic rubber has an elaborate structure, which effectively shuts out water, oxygen, carbon dioxide, salt and other causes of early structural degradation. Combined with excellent crack coverage, this performance can be sustained for a long time to protect structures from early degradation.

Provides breathability for water vapor

While acrylic rubber can effectively shut out water, oxygen, carbon dioxide, and salt, it offers the unique characteristic of selectively allowing water vapor breathability. This characteristic means that even after ARONBULLCOAT is applied to a concrete structure, the concrete can continue to breathe and reduce its moisture content. This prevents alkali-aggregate reactions and freeze damage, which are major causes of degradation.

Features of ARONBULLCOAT and application process

Table 1 compares the characteristics and intended applications for maintaining concrete structures using the super-flexible thick membrane acrylic rubber surface coating of ARONBULLCOAT. The ARONBULLCOAT Z-I and Z-II methods are ideal for preventing concrete structure degradation from salt damage, alkali-aggregate reactions, neutralization and freeze damage, while the ARONBULLCOAT Z-III method is best suited for protecting against neutralization with little impact on appearance. The Z-I method (note: vinylon mesh specification) can also be used to prevent detachment, in addition to the performance noted above.

(Table-1) Features and Applications of ARONBULLCOAT Methods

[Symbol] ◎: Most excellent, ○: Excellent, △: Good, -: Not applicable

Examples of application

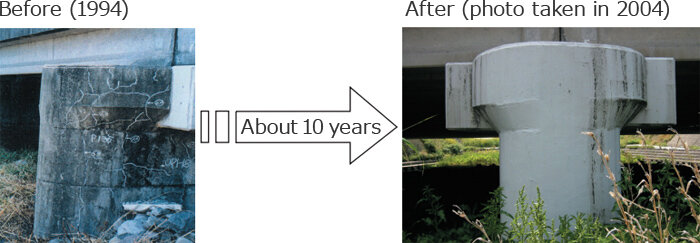

Example project for repairing a concrete structure damaged by salt damage and alkali-aggregate reactions

Although some staining can be seen on the acrylic rubber surface coating material after about 10 years, there is no marked defect in the coating, such as cracks, bubbling, or peeling.

Usage

Surface coating for civil engineering structures

Catalog

Inquiries

- Department in charge

- Construction Materials and Civil Engineering Department

- Phone number

- 0120-557-947

*9:00 am - 5:00 pm (except weekends and holidays)