Functional Adhesives Light-curable adhesives

Light-curable adhesives are available in two types: UV-light curable and visible-light curable. They are one-liquid adhesives that undergo polymerization curing at room temperature as they react with high sensitivity to wavelength regions emitted by each light irradiating device. We offer products that employ UV-light and anaerobic curing mechanisms as well as visible light and UV-light curable polymer products in order to meet the requirements of different adherend structures.

- Product name

- ARONIX and ARONTITE

- Information technology

- Electronics materials Computers Mobile information terminals

- Home electronics

- Televisions and DVDs Lighting equipment

- Environment and energy

- Reduce environmental impact

- Basic materials

- Resins and rubber additives Paints, inks, coatings and adhesives

- Automobiles

- Automobile interior Automobile exterior Engine rooms

- Lifestyle

- Interior and exterior Daily sundries Printing materials Packaging materials

Features

- Excellent workability

- One-liquid type and requires no measuring or mixing.

- Improved productivity

- Cured by light in a short time, reducing work time and cost.

- Wide selection and design

- Enables a wide selection and design of curing wavelength, anaerobicity, and cured product characteristics.

| Type | Series | |

|---|---|---|

| Light-curable adhesives | Visible light and UV-light curable types | ARONIX LCR Series |

| UV-light curable type | ARONIX UV-3000 Series |

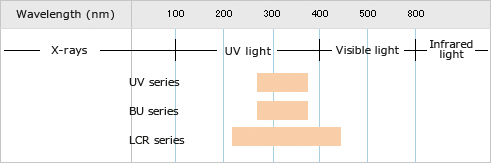

Curing wavelength regions

Capable of adhesion within a wide wavelength region of UV-light and visible light. An anaerobically curable type is also available for adherend not exposed to UV-light based on the material and shape.

Usage

- Can be used for bonding a wide range of materials, including electronic parts, metals, glass, and plastics.

- Suitable for bonding and assembling optical parts thanks to its excellent transparency.

- The low shrinkage and low stress type is best suited for precision fixing.

- Adjustable curability, hardness and viscosity.

Specifications

Visible light and UV-light curable types ARONIX LCR Series

The ARONIX LCR Series of adhesives are curable within a wide range of wavelength regions from UV-light to visible light. As visible light can easily transmit through transparent and semi-transparent materials that are impermeable to UV-light, these materials can be bonded in a few seconds with light irradiation from above. Visible light is relatively safer for the human body in comparison to UV-light, and its light source equipment is also cheaper.

Features of ARONIX LCR Series

- 1. Responds to a wide wavelength region between UV-light and visible light.

- 2.Capable of bonding transparent and semi-transparent materials (PVC, polycarbonate, acrylic, ABS, etc.) that are impermeable to UV-light in a few seconds.

- 3.Available in a wide range of grades, including a soft type with excellent stress relaxation, and a hard type selected based on the adherend material, such as resin, glass, or metal.

- 4.Suitable for bonding and assembling optical parts thanks to its excellent transparency.

- 5.The low shrinkage and low stress type is best suited for precision fixing.

| Main grades | LCR0628A | LCR0632 | LCR0305E | |

|---|---|---|---|---|

| Appearance | Colorless and transparent | Colorless and transparent | Milky white | |

| Viscosity (mPa・s, 25℃) | 12,000 | 4,000 | 130,000 | |

| Hardness (Shore D, 23℃) | 35 | 45 | 70 | |

| Refractive index (nd, 25℃) | 1.5 | 1.49 | - | |

| Water absorption rate (23℃ in water 24hr, %) | 0.91 | 0.75 | 0.10 | |

| Expansion rate (%) | 130 | 120 | 30 | |

| Tensile modulus (N/mm2) | 9.8 | 290 | 420 | |

| Glass transition temperature (℃) | 40 | 78 | 81 | |

| Thermal expansion coefficient (/℃, 30℃) | 1.5×10-4 | 1.1×10-4 | 4.4×10-5 | |

| Thermal expansion coefficient (/℃, 150℃) | 2.2×10-4 | 2.7×10-4 | 1.1×10-4 | |

| Curing shrinkage rate (%) | 4.7 | 6.5 | 3.2 | |

| Tensile shear strength (MPa) | Glass/Glass | 4.5 | 13.8 | 8.3 |

| Acrylic/Acrylic | 2.5 | 1.8 | 1.8 | |

| Features and usage | Low shrinkage, flexibility, transparency | Excellent transparency | Low curing shrinkage and low thermal expansion coefficient | |

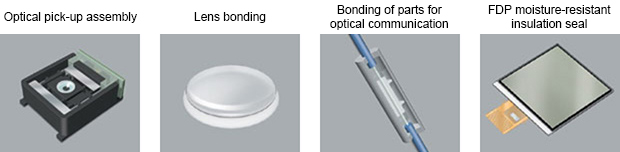

ARONIX LCR Series areas of use

UV-light curable type ARONIX UV Series

The ARONIX UV Series represents our lineup of one-liquid UV-curable resin compound products based on the ARONIX M Series of special acrylic monomers and oligomers developed by Toagosei.

Features of ARONIX UV Series

- 1.One-liquid type with excellent workability

- 2.Curable by UV-light within a short time.

Enables automation and faster-paced manufacturing, while drastically cutting down costs. - 3.Select and design from a wide range of curing methods and cured product characteristics.

Can also be used in conjunction with heat curing if needed and can be used to cure a range of film thicknesses.

Cured products can be made anywhere ranging from tough to soft with elasticity.

ARONIX UV Series areas of use

Bonding a wide range of materials, including electronic parts, metals, glass, and plastics.

Adjustable curability, hardness and viscosity.

| Grades | UV-3300 | UV-3610 *2 | |

|---|---|---|---|

| Appearance | Light yellow | Light yellow | |

| Viscosity | 4,500 | 600 | |

| Hardness (Shore D, 25℃) | 83 | 60 | |

| Flash point (℃) | 95 | 105 | |

| Number of curable passes *1 | 2 | 1 | |

| Curing shrinkage rate (%) | 8 | 8 | |

| Expansion rate (%) | 20 | 130 | |

| Tensile shear adhesive strength (MPa) | Steel/Glass | 6.0 | 5.5 |

| Glass | 5.0 | 4.5 | |

| PMMA | 5.0 | 4.0 | |

| PVC | 2.0 | 5.0 | |

| PC | 4.0 | 5.0 | |

| Features and usage | For metals and glass | For plastics | |

- *180W/cm high pressure mercury lamp condensing type, lamp height 10 cm, conveyor speed 10m/mm, Mylar coated

- *2Contains N-Vinyl-2-pyrrolidone